| Name: | Hot air tarpaulin welding machine with synchronous conveyor |

| Model: | SD-W200C |

| Voltage: | AC-220V,50/60HZ,single phase |

| Power: | 3000W |

| Speed: | 1-18m/min |

| Air pressure: | 0.35-05Mpa |

| Max hot air temperature: | 700 ℃ |

| Max welding width: | 45mm |

| Roller width: | 20/30/40/50mm |

| Up roller lift: | 20-35mm |

| Suitable fabric: | PVC fabric, Polyurethane, Polyethylene, Vinyl and other hot melt type fabric |

| Application: | Tent house,Tarpaulin,inflatable products,outdoor banner etc |

| Dimension: | 1500x750x1600mm |

| Net weight: | 260kg |

| Inquiry |

Product Description

Features:

1.Precise control by PLC and touch screen

2.Up and down rollers speed could be set in difference to avoid wrinkle welding

3.Both overlap welding and hemming welding are available

4.Max welding width could be up to 45mm

5.Auto compensation and reverse to avoid empty tapping

6.Double pedals control,more easy and comfortable

7.24h continuous work to have more output

8.Auto tape feeding and cutting to save more tape

9.Special arm and synchronous PVC conveyor design to solve the heavy tarpaulin fabric welding(1.5m/1,8m arms length for option)

10. Equipped with rear pulling roller to support heavy PE and PVC fabric output easily

11. Its available for hot air or hot wedge or both two hot systems

Welding Functions:

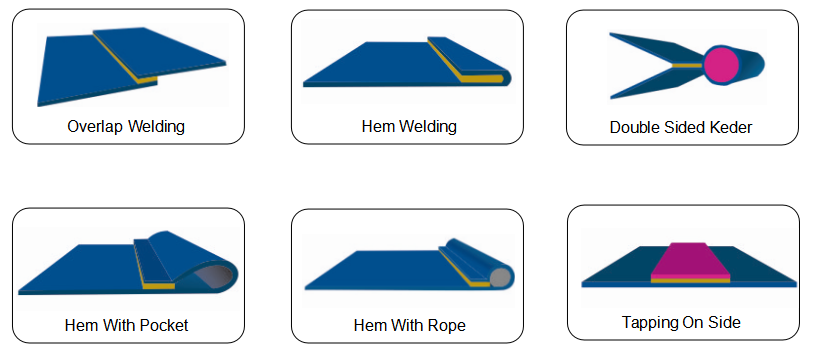

Hot air overlape welding,Hem welding,Hem with pocket,Double sided keder welding,Tapping on side

Application:

SD-W200C hot air welding machine is widely used for heavy tarpaulin fabric welding,like PE or PVC fabric,applicated in awning,tent,curtain door,tarpaulin, swimming pool and inflatable products fields.

Guestbook

Related Products

SD-W900 hot air welding machine is widely used for PVC fabric welding,like tarpaulin welding,inflatable products welding,swimming pool welding,duct products welding etc.Both overlap welding and hemming welding are available for SD-W900 hot air welder

SD-W901 PVC automatic welding machine is widely used for PVC fabric welding,like tarpaulin welding,inflatable products welding,swimming pool welding,duct products welding etc.Both overlap welding and hemming welding are available for SD-W901.It's perfect

SD-W200 Hot air welding machine for tarpaulin could weld PVC tarpaulin and PE tarpaulin to joint two pieces of tarpaulin together or tarpaulin hem welding with rope or not.Sumdawelder offer the best sale price for tarpauling hot air welding machine.

Send Email

Send Email Jim-y0713

Jim-y0713